Here you are method statements related to the repairing and protection of concrete

Kimia has optimized the composition of its cement mortars to ensure their adequate durability and effectiveness, working in four directions:

- Studying the behavior over time of its products/application cycles;

- Ensure, through high skills of application, a quick and "foolproof" laying;

- Certify in accordance with current regulatory standard the products proposed;

- Optimize the products by guaranteeing performances (such as adhesions after 1 and 7 days already compliant with regulatory requirements usually required after 28 days of curing, improved expansive properties, volumetric stability) which, although not strictly required by the norms, allow greater security and better success of interventions.

The best evidence of the reliability of our cycles is given by the many yards which remain, decades later, in perfect conditions.

Please find description of our interventions for the following applications:

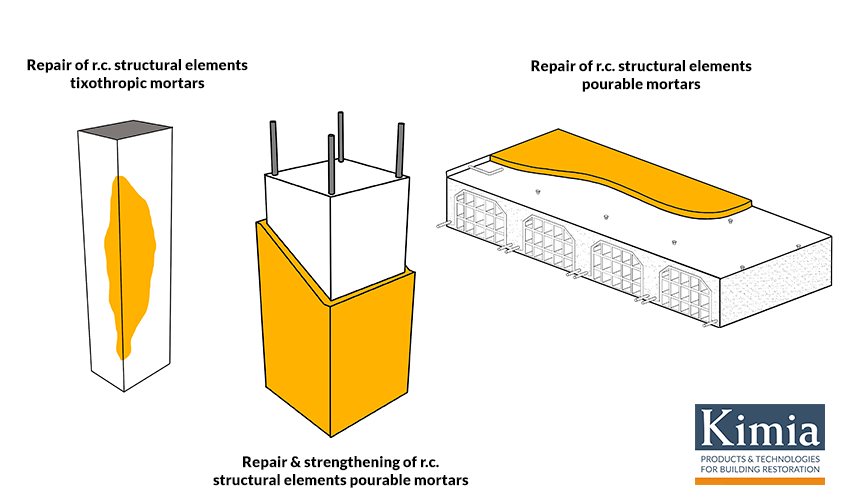

► Repair of R.C. structural elements

► Skimming of concrete surfaces and renders

► Protection against carbonation of R.C. substrates

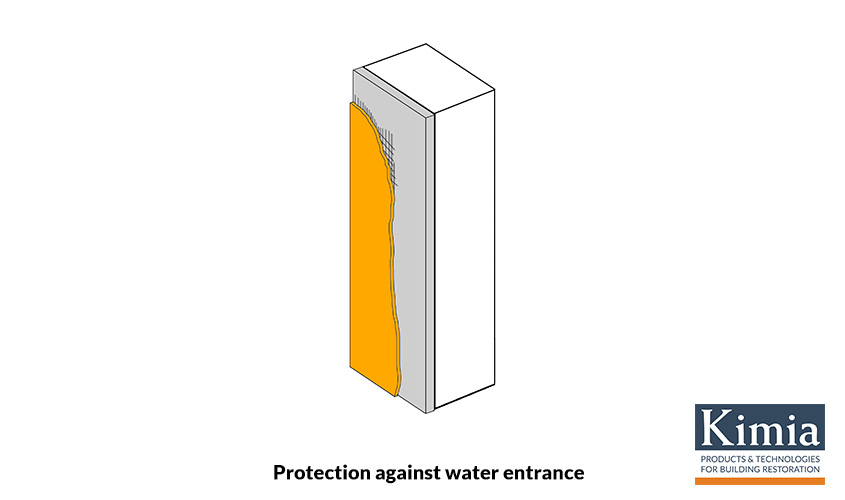

► Protection against water entrance

► Protection against chemical aggressions

Repair of R.C. structural elements

Preparation of substrates

Prepare all surfaces to be restored by completely removing all the deteriorated concrete with a hand or power chisel or with other suitable means, such as hydro-scarifying, to obtain a solid, sufficiently-rough substrate with no detached portions.

If the deteriorated concrete has been removed with a hand or power chisel, clean all exposed steel reinforcement with a brush or by hydro-sandblasting to remove the rust and bring the steel reinforcement back to a bare metal finish.

Hydro-sandblasting is not required if the surface has been prepared by hydro-scarifying. However, if the time between hydro-scarifying and treating the steel reinforcement is particularly long due to on-site logistics, hydro-sandblasting must be carried out.

Replace any steel reinforcement which has been cut or damaged, or which is highly corroded, with new reinforcements.

Clean all surfaces to be restored and saturate the substrate leaving a dry surface (s.s.d.) by hydro-cleaning.

Protection of steel reinforcement

Treat the steel reinforcement by brush-applying one coat of one-component anti-corrosion cementitious mortar Betonfix KIMIFER.

In case Betonfix MONOLITE N or Betonfix MONOLITE R mortars are used, it is not necessary to protect the treat the steel reabrs with Betonfix KIMIFER.

Restoration operations

When Betonfix KIMIFER is still wet, restore the concrete using one of the following products:

- Pourable R4 products: Betonfix CR or Betonfix HCR

- Tixothropic R4 repair mortar: Betonfix FB, Betonfix MONOLITE N, Betonfix MONOLITE R

- Tixothropic R3 repair mortar: Betonfix RCA, Betonfix TX

- Tixothropic R2 repair mortar Betonfix RR

These cementitious mortars must be mixed with the amount of water or latex indicated in their relative Technical Data Sheet to form a well-blended, lump-free mix. Since water content or latex have an influence on the properties of the mortar, take special care to prevent it evaporating off too quickly while curing.

In hot or windy weather, we recommend using the damp-curing technique or applying an anti-evaporation product to prevent rapid evaporation of the mixing water. The anti-evaporation product must be compatible with the successive skimming or protective layer, and must be removed if necessary.

- In case of tixothropic products, apply the mortar with a trowel within the application temperature range indicated in the Technical Data Sheet. If the thickness to be restored is more than the indicated values, apply the mortar in several coats and reinforce it by inserting electro-welded mesh to compensate for hygrometric shrinkage and guarantee sufficient contrast to the slight expansions of the mortar. The size (diameter of wire and mesh size) must be according to design specifications. Tamp the mortar. The waiting time depends on climatic conditions, and tamping should be carried out when a small imprint remains after touching the surface with a finger.

- In case of pourable mortars, cast them within the application temperature range indicated on the Technical Data Sheet. Pour the mix in a continuous flow from one side only into the prepared area, making sure that all air is expelled. If applied into formwork, coat the formwork with a stripping compound before casting to prevent it drawing off any of the mixing water. Reinforce the concrete with electro-welded steel mesh. The dimensions of the mesh (diameter of steel wire and size of mesh) must be according to design specifications, so as to compensate for hygrometric shrinkage and to guarantee sufficient contrast to the expansive action of the mortar. Embed the mesh at around the mid-point of the layer to be restored and connect it to the steel reinforcement.

Skimming

When the repair is done using Betonfix MONOLITE N, Betonfix MONOLITE R and Betonfix RR, there is usually no need to apply a final skimming. If a finer finish is required (in case of interventions undertaken with all the other tixothropic mortars), or if the quality of finish obtained - which depends on the type of formwork used – is not good (in case of castable grouts), skim the surfaces once the repai mortar has cured with Betonfix RS or Betonfix R30.

PS: Before skimming the surfaces, in case of castings done using formwork, remove all traces of stripping and/or anti-evaporation agent by hydro-sandblasting.

Protection

Final protection of the surfaces may be carried out using Kimicover BLINDO.

Skimming of concrete surfaces and renders

Prepare the substrate by removing all crumbling or detached areas to obtain a solid substrate. Remove all traces of dust or other elements which could prevent the product adhering correctly. If the substrate is painted, the paint must be even and must be well adhered to the substrate.

Apply Betonfix RS or Betonfix R30 on clean substrates, which must be damp in case of absorbent materials (concrete and render), dry in case of old paintwork, with a smooth metal trowel in layers from 1 to 3 mm thick, then finish off the surface with the same trowel or a sponge float. Thicker layers, up to a maximum of 6 mm, must be applied in two layers.

Place alkaline-resistant glass fibre mesh Kimitech 350 between the first and second layer. Overlap the edges of each strip of glass fibre mesh by at least 10 cm. Net will be used any time the substrate is composed by various materials.

Protection against carbonation of R.C. substrates

Surfaces to be protected with Kimicover BLINDO must be perfectly solid. Repair any areas in concrete which are in poor condition with mortars of the Betonfix range of products, and wait at least 7 days before application of the product. Remove all traces of dirt, dust, grease, oil, paintwork, saline efflorescence, mould and moss which could affect the right adhesion of the painting to te substrate.

In case of old surfaces, the choice of the right cleaning depends on the type of dirt: cold water is usually sufficient. Cleaning the surface with hot water or steam is particularly recommended if oil or grease is present. Sand-blasting may also be used.

If the surface is not dirty, it may simbly be brushed down with a stiff brush and blown with compressed air to remove the dust. On surfaces where the type of curing cycle used is unsure, or if they are crumbly or have low absorbency, use Kimitech ACR for the preliminary treatment cycle. The primed surface must never be “shiny”.

Kimicover BLINDO may be applied using traditional application techniques: by brus, roller or spray. For effective, complete covering of the surface, apply at least two coats. Under normal humidity and temperature conditions, wait at least 24 hours between each coat, and in all cases, only when the previous coat is completely dry.

Protection against water entrance

Prepare the substrate by removing all crumbling or detached areas to obtain a solid substrate. Remove all traces of dust or other elements which could prevent the product adhering correctly. Apply the two-component elastic cementitious mortar Kimicover DUO on clean and dump substrates to form a layer at least 2 mm thick.

- If powder is mixed with 33% of latex, apply the product with a smooth metal trowel or by spray with a rendering machine, fitted with a spraying lance for skimming compound.

- If powder is mixed with 50% of latex, apply the product by brush or roller.

In areas where there is the risk of crack-formation due to settling, or on structures particularly subjected to dynamic stress, the product must be applied in two layers, with alkaline-resistant glass fibre mesh Kimitech 350 placed between the first and second layers. Overlap the edges of each strip of glass fibre mesh by at least 5 cm.

After at least 7 days from protective waterproofing, the surfaces will be protected with Kimicover BLINDO, to be applied using traditional application techniques: by brus, roller or spray. For effective, complete covering of the surface, apply at least two coats. Under normal humidity and temperature conditions, wait at least 24 hours between each coat, and in all cases, apply the second coat only when the previous one is completely dry.

Protection against chemical aggressions

Completely remove loose particles, cement laitance, dust, paint, oil, form release compounds and other deleterious substances. In case of oils and grease:

- If the substrate is superficially impregnated, vigorously clean it with a 10% water and soda solution or detergents and then rinse thoroughly several times with clean water.

- If oils and grease have penetrated deeply into the substrate, the contaminated concrete must be removed by scarifying and levelled with appropriate Betonfix mortar or Kimitech ECF reinforced with a net.

In case:

- surfaces contain loose particles → apply Kimicover FIX primer;

- there is water in counter pressure → block local seapage or general water spilling with Betonfix WW.

Kimitech K40 NF (epoxy resin) or Kimicover 301 NF (polyurethan resin) can be applied with brush, roller, or airless gun in at least two coats. The second coat must be applied within the time stated in the TDS of the products. In case of very absorbent substrates, not previously treated with Kimicover FIX or three-component epoxy-cementitious system Kimitech ECF, the first coat of Kimitech K40 NF may be diluted 5 to 10% with clean water, while the first coat of Kimicover 301 NF can be diluted 5 to 15% with Solvente EPOX.

Info & Technical Support

Other method statements here. If you want to get further info or technical support please fill in the form to get in touch with our Technical Department.